Embracing the Next Manufacturing Revolution: 5 Emerging Trends for 2024 and Beyond

- Published on - Jan 23, 2024

-

5 mins read

-

Total views -

Total views -

-

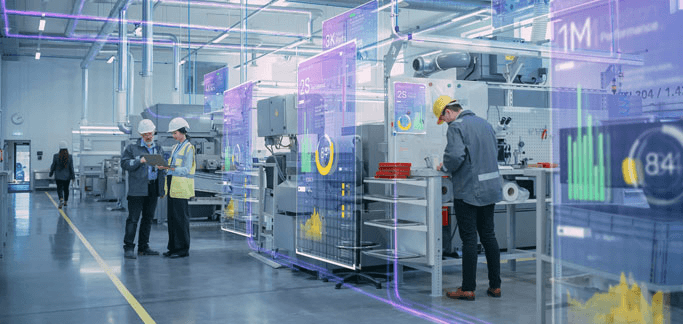

In recent years, emerging technologies have transformed the traditional manufacturing landscape, paving the way for Manufacturing 4.0. The new era is characterized by connectivity, efficiency, and flexibility to power smart and adaptable production systems. As the factories of tomorrow evolve, various innovations in areas such as artificial intelligence, virtual reality, and additive manufacturing are reaching a maturity level for large-scale deployment. With the next industrial revolution underway, the accelerated adoption of these key technologies will enable manufacturers to gain greater agility, precision, and sustainability. From AI-powered robots to Immersive extended realities, here are five trends set to transform manufacturing over the next few years.

What to Expect in 2024: Five Key Trends

Leveraging Digital Twins to Optimize Manufacturing Operations

Digital twins are detailed virtual models that accurately reflect physical assets and systems. They integrate data from sensors in production equipment and final products to provide real-time insights into performance and operating conditions. Digitally mirroring the physical world allows manufacturers to assess the current state of machinery and extrapolate optimal parameters for efficiency and quality. As technology advances, digital twins will play a valuable role in everything from product prototyping to factory floor planning and supply chain coordination. Manufacturers can leverage digital twin simulations to optimize their end-to-end operations, envisioning different "what if" scenarios to improve productivity and throughput. This ability to virtually stress test systems will allow greater innovation with less risk.

Additive Manufacturing Enables On-Demand Customization

Additive manufacturing, also known as 3D printing, has progressed rapidly from a niche prototyping process to the production of finished components. As specialized metal printer costs decrease, additive techniques offer new frontiers in design complexity, customization, and waste reduction. Additive printing unlocks geometries impossible for conventional subtractive machining, pushing boundaries for lightweight, high-performance designs across industries from aerospace components to complex microelectronics and biomedical implants. Where traditional, "subtractive" manufacturing was dependent on cutting away material from a base form, additive printing builds up products layer-by-layer according to precise digital specifications. By localizing production through compact 3D printers, manufacturers can easily customize or update products on the fly based on customer specifications. Full-scale additive production of specialized parts will vastly expand by 2024. The flexibility of this method will enable the next generation of mass customization in manufacturing.

IIoT Empowers End-To-End Supply Chain Visibility

IIoT consists of networked sensors integrated with production systems and inventory. They empower tracking all inputs, allowing high-quality, socially responsible supply chain management. Machine sensors track details like equipment effectiveness, vibration anomalies, or temperatures in real-time and share this data instantly over IIoT networks for actionable insights. As analytics platforms leverage artificial intelligence and machine learning, they identify inefficiencies and refine operations autonomously. Over the next few years, rapidly improving connectivity and intelligence facilitated through cloud data storage and computing power will create highly visible, self-orchestrating production ecosystems. The Industrial Internet of Things (IIoT) acceleration across factory floors and supply chains is set to serve rising manufacturing needs.

AR and VR Enable Risk-free Training and Maintenance

Emerging extended realities, augmented (AR) and virtual (VR), overlay digital information onto the real operating environment. Modern headsets no longer require bulky equipment or isolate users like early versions. Enhanced mobility and simulation quality are making these technologies versatile across manufacturing. Users can access detailed supplemental content or share live views with remote collaborators to troubleshoot issues in context. Over the next couple of years, increasing numbers of operators will use AR glasses and handheld devices to boost productivity and accuracy. For example, warehouse pickers may view optimized routes projected onto warehouse shelves. Meanwhile, VR systems provide immersive training simulations without any risk to expensive machinery, acclimating personnel rapidly. Their widespread adoption in manufacturing will give crucial sensing capabilities and remote collaboration opportunities in 2024.

AI and ML Create Flexible, Collaborative and Dexterous Production Robots

Artificial intelligence (AI) and machine learning (ML) are enabling the current wave of modern automation and robotics. While industrial robots have performed rigid functions for decades, AI-enhanced robots adaptively handle more subtle tasks. Advanced computer vision guides navigation, part identification, and real-time quality evaluation, while soft pressure-sensitive grippers allow handling delicate objects. Where previous automation often focused solely on boosting speed or endurance in fixed processes, smart robotics address flexibility demands. Combining AI and ML software with new hardware advances like responsive tactile sensors will create highly dexterous, collaborative production assistants requiring no coding changes to switch between product lines. Cognitively-enhanced robots will be integral components across leading manufacturing ecosystems in the next few years.

What's Ahead

As technological innovations reach mainstream adoption, they will form the core building blocks of Manufacturing 4.0, transforming rigid assembly lines into flexible smart factories. Combining these symbiotic trends will enable mass customization and on-demand production at scale. Software and data analysis will continuously optimize hardware performance as new insights are dynamically incorporated into designs and processes. Equally important is to support cleaner, safer working environments with reduced waste, emissions, and energy use that translate to lower costs and supply chain risks. As the future of production promises to be interconnected, nimble, and intelligent, manufacturers that embrace these new opportunities will gain improvements in agility, sustainability, and precision for continued growth and success.

You may also like

Fill in your details to get a call back

Connect With Us

Please Fill in Your Details and We'll Call You Back!

Please Fill in Your Details and We'll Call You Back!