India’s manufacturing sector is entering a new era driven by digital technologies, automation and data-led decision-making. With initiatives like Make in India, PLI schemes and rising global demand, manufacturers—especially SMEs—are under pressure to become smarter, faster and more resilient

In 2026, technology will be the key differentiator between manufacturers who merely survive and those who scale sustainably. Here are the top technology trends that will shape India’s manufacturing industry in 2026, with a strong focus on practical adoption for Indian SMEs.

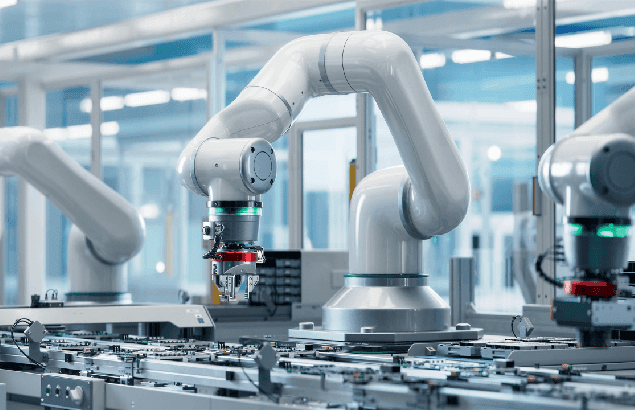

1. Smart Manufacturing and Industry 4.0 Goes Mainstream

Industry 4.0 is no longer limited to large enterprises. In 2026, Indian manufacturing SMEs will increasingly adopt smart manufacturing technologies to improve efficiency, visibility and control across operations.

Key elements include:

- Connected machines and sensors

- Real-time production monitoring

- Data-driven decision-making

- Digital dashboards for plant performance

By integrating operational data from shop floors, SMEs can reduce downtime, optimise production cycles and improve overall equipment effectiveness (OEE).

2. Industrial IoT (IIoT) Expands Across the Factory Floor

The Industrial Internet of Things (IIoT) will be a cornerstone of manufacturing transformation in 2026. Sensors embedded in machines, tools and utilities will continuously capture operational data.

For Indian manufacturers, IIoT enables:

- Predictive maintenance to reduce breakdowns

- Energy monitoring and optimisation

- Remote monitoring of multiple plants

- Improved quality control

With falling sensor costs and better connectivity, IIoT adoption will accelerate even among mid-sized and small manufacturing units.

3. AI-Driven Predictive Analytics and Automation

Artificial Intelligence will play a bigger role in manufacturing operations in 2026, especially in predictive analytics and process automation.

Common AI-driven use cases include:

- Predicting machine failures before they occur

- Optimising production schedules

- Detecting quality defects in real time

- Automating routine operational decisions

For SMEs, AI-driven insights help reduce wastage, improve consistency and maximise asset utilisation—without heavy manual intervention.

4. Hybrid Cloud for Manufacturing IT and OT Systems

Manufacturing environments require a balance between real-time operations and scalable IT systems. In 2026, hybrid cloud architectures will become the preferred model for Indian manufacturers.

Why hybrid cloud works:

- On-premise systems for latency-sensitive shop-floor operations

- Cloud platforms for analytics, reporting and scalability

- Secure data storage with compliance readiness

- Business continuity and disaster recovery

Hybrid cloud enables manufacturers to modernise legacy systems while retaining control over critical operational data.

5. Edge Computing for Real-Time Manufacturing Decisions

As factories generate massive volumes of data, processing everything in the cloud is neither efficient nor practical. In 2026, edge computing will play a vital role by processing data closer to machines and production lines.

Benefits for manufacturers include:

- Faster response times

- Reduced network bandwidth usage

- Improved reliability in remote locations

- Real-time alerts and control

Edge computing is especially relevant for plants operating in areas with connectivity constraints or requiring instant decision-making.

6. Cybersecurity for Connected Manufacturing Environments

As factories become more connected, cybersecurity risks increase. In 2026, manufacturing SMEs will prioritise OT and IT security convergence to protect production systems.

Key focus areas include:

- Securing industrial networks and endpoints

- Protecting machine data and IP

- Network segmentation and access control

- Continuous monitoring and threat detection

Cyber incidents can halt production, cause financial loss and damage customer trust—making security a critical technology investment.

7. Advanced Connectivity Powering Digital Factories

Reliable, high-speed connectivity will underpin every digital manufacturing initiative in 2026. Indian manufacturers will increasingly adopt:

- High-speed fibre connectivity

- SD-WAN for multi-plant operations

- Secure VPNs for remote monitoring

- Redundant networks for uptime assurance

Strong connectivity ensures seamless integration between machines, cloud platforms, ERP systems and analytics tools—enabling truly digital factories.

What This Means for Indian Manufacturing SMEs

Technology adoption in 2026 will focus on visibility, automation, resilience and scalability. Manufacturing SMEs that invest in smart factories, IIoT, AI-driven analytics and secure connectivity will be better equipped to compete in both domestic and global markets.

Digital transformation is no longer about future readiness—it is about immediate operational efficiency and long-term growth.

The TTBS Perspective

Tata Tele Business Services (TTBS) enables Indian manufacturers to build secure, connected and intelligent factories. With solutions spanning high-speed connectivity, SD-WAN, cloud enablement and managed cybersecurity, TTBS supports manufacturing SMEs at every stage of their digital journey.

As India’s manufacturing industry evolves in 2026, TTBS helps businesses transform operations, safeguard critical systems and scale with confidence.

4 mins read

Total views -

Total views -